Introduction to CNC

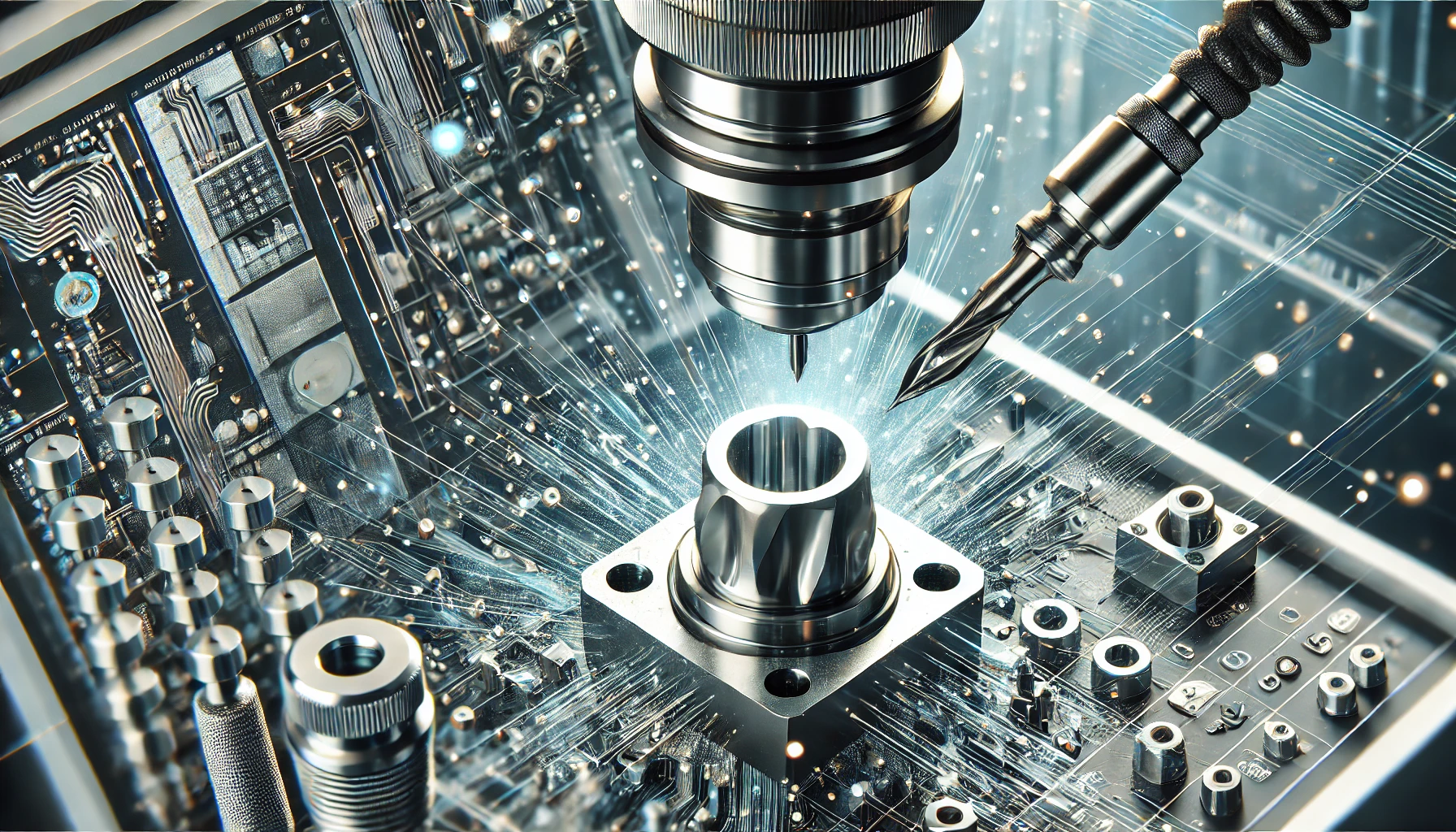

CNC stands for **Computer Numerical Control**. It is a technology used in the manufacturing industry that involves the automated control of machining tools (such as drills, lathes, mills, and 3D printers) by means of a computer. CNC machines are used to create parts and components with high precision and repeatability by following programmed instructions. This technology has revolutionized the manufacturing industry by enabling the production of complex and intricate parts that would be difficult or impossible to create manually.

History of CNC

The concept of numerical control (NC) began in the late 1940s and early 1950s. John T. Parsons, in collaboration with the Massachusetts Institute of Technology (MIT), developed the first NC machine to aid in the post-war manufacturing effort. Initially, NC machines were hardwired, and instructions were given via punched tape. By the mid-1960s, NC technology was widely adopted in metalworking production environments across the United States.

The advent of microprocessor technology in the 1970s and 1980s allowed computers to be directly connected to NC machines, giving rise to CNC. This advancement enabled the automation of complex machining processes, significantly improving precision, efficiency, and repeatability.

How CNC Works

Components of a CNC System

A CNC system typically consists of the following components:

- **Computer**: The brain of the CNC system, which runs the software that controls the machine.

- **Controller**: The interface between the computer and the machine tool, which interprets the computer’s instructions and sends signals to the machine’s motors.

- **Machine Tool**: The physical device that performs the machining operations, such as cutting, drilling, or milling.

- **Drive System**: The motors and other components that move the machine tool along its axes.

- **Feedback System**: Sensors and other devices that provide real-time data to the controller, ensuring accuracy and precision.

Programming CNC Machines

CNC machines are programmed using a specialized language called G-code. G-code consists of a series of instructions that specify the movements and operations of the machine tool. These instructions are typically generated using computer-aided design (CAD) and computer-aided manufacturing (CAM) software, which translate a digital model of the part into a sequence of machine commands.

The CNC controller reads the G-code and sends signals to the machine’s motors, which move the tool along the specified paths. The feedback system continuously monitors the tool’s position and makes adjustments as needed to ensure accuracy.

Applications of CNC

CNC technology is used in a wide range of industries and applications, including:

- **Aerospace**: Manufacturing complex components for aircraft and spacecraft.

- **Automotive**: Producing parts for cars, trucks, and other vehicles.

- **Medical**: Creating precision instruments and implants for medical use.

- **Electronics**: Fabricating circuit boards and other electronic components.

- **Furniture**: Crafting intricate designs and patterns in wood and other materials.

Advantages of CNC

CNC technology offers several advantages over traditional manual machining:

- **Precision**: CNC machines can produce parts with extremely tight tolerances and high accuracy.

- **Repeatability**: Once a program is created, the machine can produce identical parts consistently, reducing variability and waste.

- **Efficiency**: CNC machines can operate continuously and at high speeds, increasing productivity and reducing lead times.

- **Flexibility**: CNC machines can be quickly reprogrammed to produce different parts, allowing for rapid changes in production.

- **Safety**: Automation reduces the need for manual intervention, minimizing the risk of accidents and injuries.

Challenges and Future Trends

Despite its many advantages, CNC technology also presents some challenges:

- **Cost**: CNC machines and the associated software can be expensive, making them less accessible for small businesses.

- **Complexity**: Programming and operating CNC machines require specialized skills and training.

- **Maintenance**: CNC machines require regular maintenance to ensure optimal performance and prevent breakdowns.

Looking ahead, several trends are shaping the future of CNC technology:

- **Integration with IoT**: The Internet of Things (IoT) is enabling real-time monitoring and control of CNC machines, improving efficiency and reducing downtime.

- **Artificial Intelligence**: AI and machine learning are being used to optimize machining processes, predict maintenance needs, and enhance quality control.

- **Additive Manufacturing**: Combining CNC machining with 3D printing is opening new possibilities for creating complex and customized parts.

- **Sustainability**: Advances in materials and processes are reducing the environmental impact of CNC machining, promoting more sustainable manufacturing practices.

Conclusion

CNC technology has transformed the manufacturing industry by enabling the production of high-precision, complex parts with efficiency and repeatability. As technology continues to evolve, CNC machines are becoming more intelligent, flexible, and integrated, paving the way for new innovations and applications. Understanding the principles and capabilities of CNC is essential for anyone involved in modern manufacturing, from engineers and designers to operators and managers.