Introduction

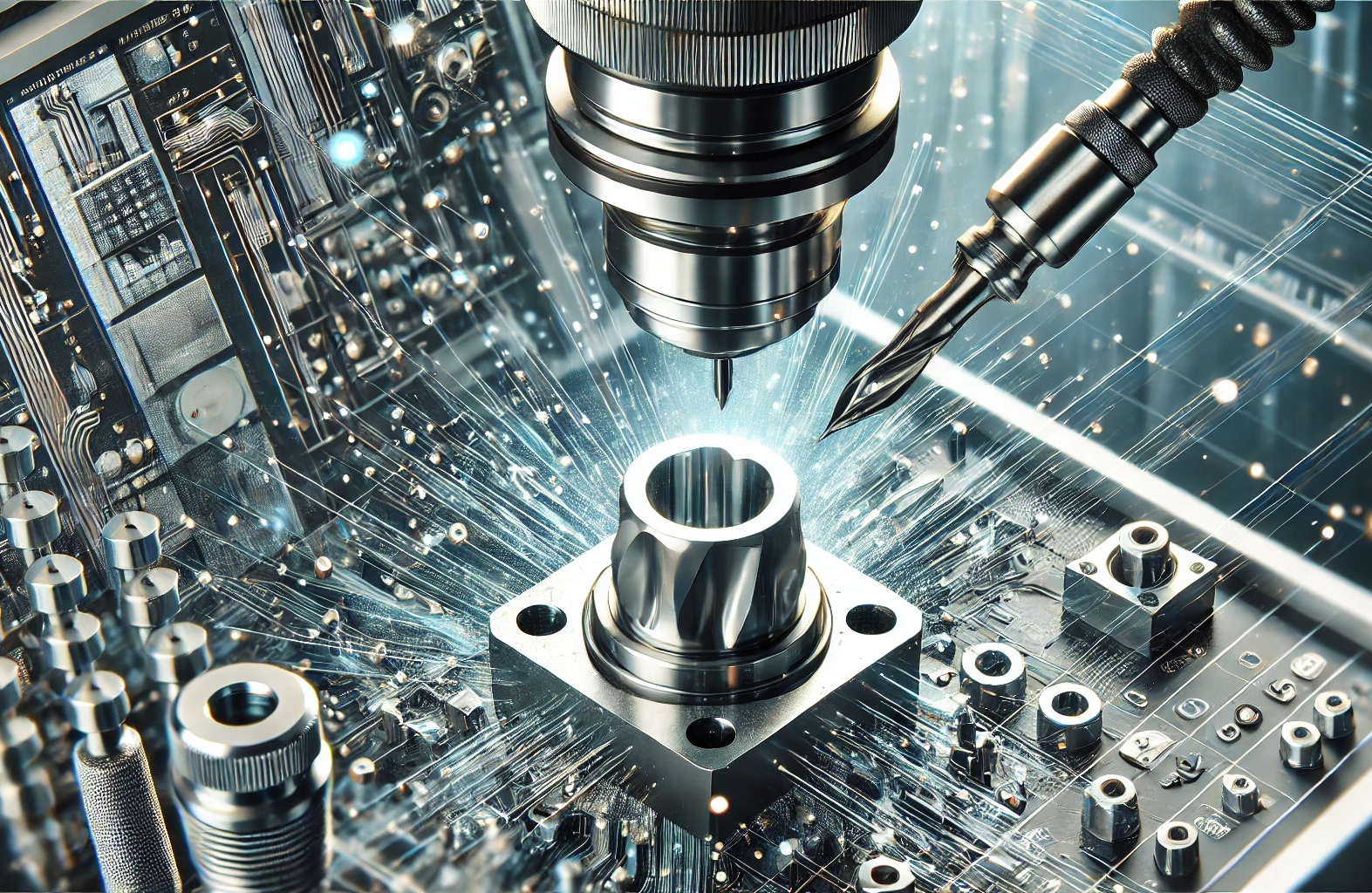

A CNC router is a computer-controlled machine designed to cut various materials with precision and efficiency. Its applications span multiple industries, including woodworking, metalworking, and plastic fabrication. In recent years, CNC routers have become a staple in manufacturing environments due to their ability to handle complex shapes, enhance productivity, and maintain high levels of accuracy.

To understand the importance of CNC routers, it is essential to explore their components, technology, and benefits. This paper provides an in-depth analysis of CNC routers, their operational capabilities, and their implications for factories, distributors, and manufacturers. We will also discuss how businesses can leverage CNC router technology to optimize production efficiency.

CNC routers come in various configurations, including 3-axis, 4-axis, and 5-axis machines. For example, a 3-axis CNC router can handle basic cutting tasks, while a 5-axis CNC router can manage more complex jobs. To help businesses decide whether to invest in a new or used CNC router, we will discuss the factors that influence this decision, including technical requirements, accuracy, and cost.

This research paper will also touch on the importance of choosing the right **cnc router** for your business needs, offering insights into how factories, distributors, and resellers can make informed decisions. For more comprehensive details on CNC routers, you can explore additional resources available at BCNC Hardware.

Understanding CNC Routers: Core Components and Functions

The Core Components of CNC Routers

CNC routers consist of several key components that work together to ensure precise cutting operations. These components include:

- Frame: Usually made from aluminum or steel, the frame supports the entire machine and ensures stability during operation.

- Spindle: The spindle is the cutting tool that rotates at high speeds to carve into the material. It is essential for achieving the required precision.

- Stepper Motors: These motors control the movement of the machine along the X, Y, and Z axes.

- Controller: The controller interprets the design files and sends instructions to the stepper motors.

- Work Table: The material to be cut is placed on the work table, which is typically movable in some configurations.

Understanding these components is crucial for manufacturers when choosing a CNC router that fits their specific needs. A high-quality **cnc router** will offer precise control over each of these elements, ensuring consistent, reliable results. To learn more about CNC router configurations and their uses, visit BCNC Hardware’s categories page.

How CNC Routers Work

The operation of a CNC router involves several stages, beginning with the creation of a design using Computer-Aided Design (CAD) software. Once the design is complete, it is translated into machine code (typically G-code) through a CAM (Computer-Aided Manufacturing) process. The CNC controller then interprets this code and sends instructions to the router’s motors, guiding the movement of the cutting tool.

The CNC router’s spindle moves along the X, Y, and Z axes, cutting materials based on the specified design. CNC routers are capable of cutting various materials, including wood, plastic, metal, and foam. The precision offered by these machines makes them ideal for complex shapes and detailed carvings.

Types of CNC Routers

3-Axis CNC Routers

The 3-axis CNC router is the most common type of router and is widely used in woodworking and metalworking. It moves along three axes—X, Y, and Z—making it suitable for tasks like engraving, cutting, and drilling. The simplicity of a 3-axis CNC router makes it a cost-effective option for many businesses, particularly those focused on producing flat or relatively simple parts.

4-Axis CNC Routers

A 4-axis CNC router adds a rotational movement (the A-axis) to the standard three-axis movement, allowing for more complex cuts. This type of router is ideal for businesses that need to produce cylindrical parts or perform intricate carvings. The 4-axis CNC router offers enhanced flexibility and precision, making it a valuable tool for manufacturers working with complex shapes.

5-Axis CNC Routers

The 5-axis CNC router is the most advanced option, offering movement along five axes. This machine is capable of cutting materials from almost any angle, making it ideal for creating 3D parts with complex geometries. The ability to cut along multiple axes simultaneously dramatically reduces the time required for intricate cuts.

While 5-axis CNC routers are more expensive than their 3-axis and 4-axis counterparts, they offer unparalleled flexibility and precision. These machines are commonly used in aerospace, automotive, and medical industries for the production of highly complex components.

Benefits of CNC Routers

Enhanced Productivity

CNC routers significantly enhance productivity by automating the cutting process. With a CNC router, manufacturers can produce parts faster and with greater consistency than traditional manual methods. This increased efficiency helps businesses meet tight production deadlines and reduce labor costs.

High Precision and Accuracy

CNC routers offer unparalleled precision, ensuring that each part is produced to exact specifications. This level of accuracy is crucial for industries like aerospace and medical device manufacturing, where even minor deviations can lead to significant issues. The use of CAD and CAM software further enhances the precision of CNC routers by minimizing human error.

Cost Efficiency

While CNC routers represent a significant upfront investment, they offer long-term cost savings by reducing labor costs and material waste. The ability to automate production processes means that businesses can operate with fewer employees, and the precision of CNC routers ensures that materials are used efficiently, reducing waste.

Choosing Between New and Used CNC Routers

One of the key decisions that businesses face is whether to invest in a new or used CNC router. While new machines offer the latest technology and features, used CNC routers can be a cost-effective option for businesses on a budget. However, it is essential to consider factors like the machine’s condition, technical requirements, and the complexity of the parts being produced.

New CNC routers come with the advantage of warranties and technical support, which can be crucial for businesses that rely heavily on their machines. On the other hand, used CNC routers may have outdated technology and be more prone to breakdowns. It is essential to carefully evaluate the condition of a used CNC router before making a purchase.

For those considering purchasing a CNC router, whether new or used, BCNC Hardware offers a wide selection of high-quality machines. Check out their selection of CNC routers to find the right one for your business needs.

Conclusion

conclusion, CNC routers are a versatile and valuable tool for businesses in various industries, from woodworking to aerospace. By automating the cutting process, these machines enhance productivity, improve precision, and reduce costs. Whether you are looking for a 3-axis, 4-axis, or 5-axis machine, it is essential to choose a CNC router that meets your specific needs.

Factories, distributors, and resellers can benefit greatly from incorporating CNC routers into their production lines. Whether investing in a new or used machine, it is crucial to consider factors like accuracy, technical requirements, and cost. For more information on CNC routers, including tips on choosing the right machine, visit the BCNC Hardware resources.